REAL TIME REMOTE POWER LINE MONITORING

THE RT-RPLM is an advanced cloud-based temperature monitoring system for power transmission lines. The solution has great benefit in helping the grid utility operator to remotely and continuously monitor the core cable temperature along with other parameters in an easy, cost-effective and reliable way.

Accurate measurement of cable catenary temperature with our Dynamic Loading Response (DLR) algorithm and temperature sensor, can provide 15-28% more power for maximum power transfer.

our RT-RPLM system takes the guesswork out of dynamic ratings. Whereas conventional systems attempt to predict the effect of increased loading on overhead power lines, the system measures the actual temperature of the conductors in real time, enabling increased load to be applied safely and efficiently.

Our system is completely passive sensors, (no electronics), which means they are robust and can withstand the emergency temperatures (such as 250°C) that are permitted for short periods with ACSR cables. No electronics, no wires and no batteries. RT-RPLM sensors are durable, easy to install, and maintenance free. They can be applied to any phase of any AC or DC line of any voltage.

Benefits of System

•Increased transmission system efficiency.

•Decreased or deferred capital costs through improved utilization of existing assets.

•Decreased system congestion costs.

•Increased situational awareness and operational flexibility of the transmission system.

Advantages of RT-RPLM

– No limit to conductor voltage

– Measures conductor temperature in real time.

– Measures one phase or all three.

– No Electronics. Sensors do not require a power source or active electronics.

– Easy, quick One-Bolt installation without interrupting service.

– Operates in a high electromagnetic field environment.

– Backhaul communication options.

– Compatible with all power line configurations –AC, DC, multiple phases, any voltage, any line geometry.

Eliminate Transmission Constraints & Congestion

RT-RPLM ratings can be used to eliminate or reduce congestion costs. The combination of actual conductor temperature and learning over time produce ratings that are reliable and dependable.

Recognize Extreme Events

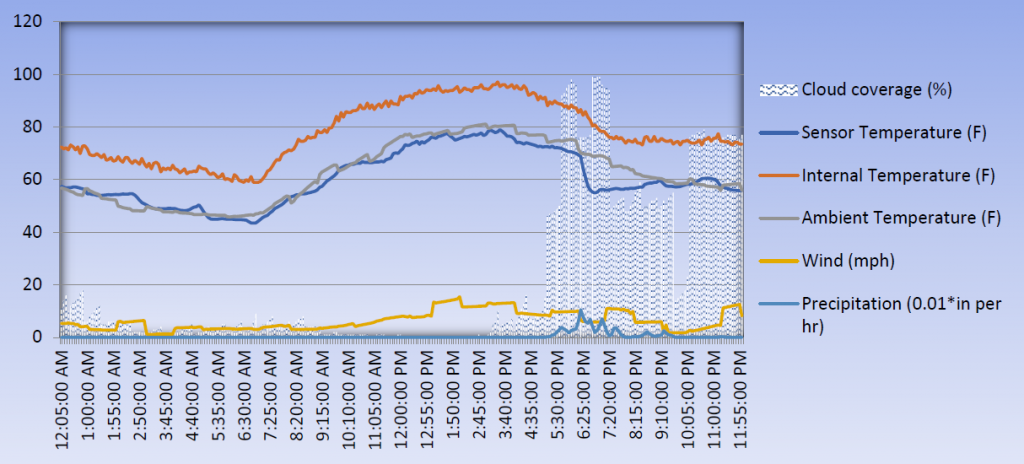

Extreme events, such as severe ice loading or emergency loading conditions, are recognized and the resulting changes in conductor behavior are automatically incorporated in Torino’s data reporting.

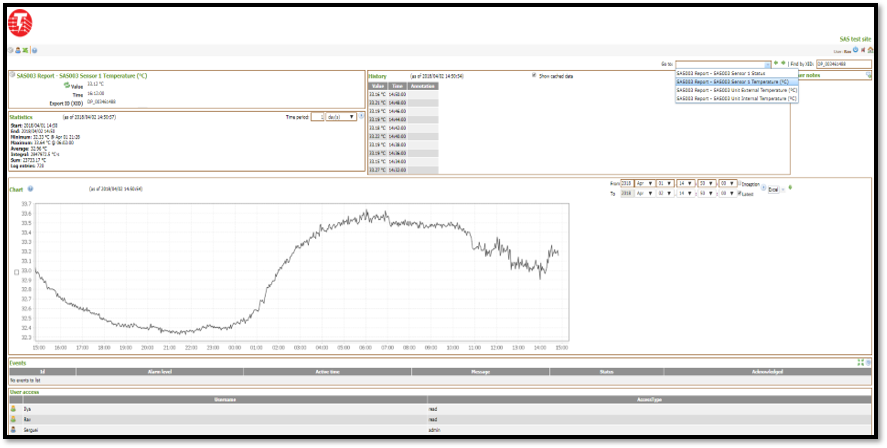

SENSOR DATA

Real time data can be viewed using SCADA software and is download from the server in real time.

•Users can specify daily reports with graphical information.

Data can be superimposed on the SCADA current/load data providing for actionable alarms based on real-time temperature data.

• All the data can placed on the customer’s server for complete access.

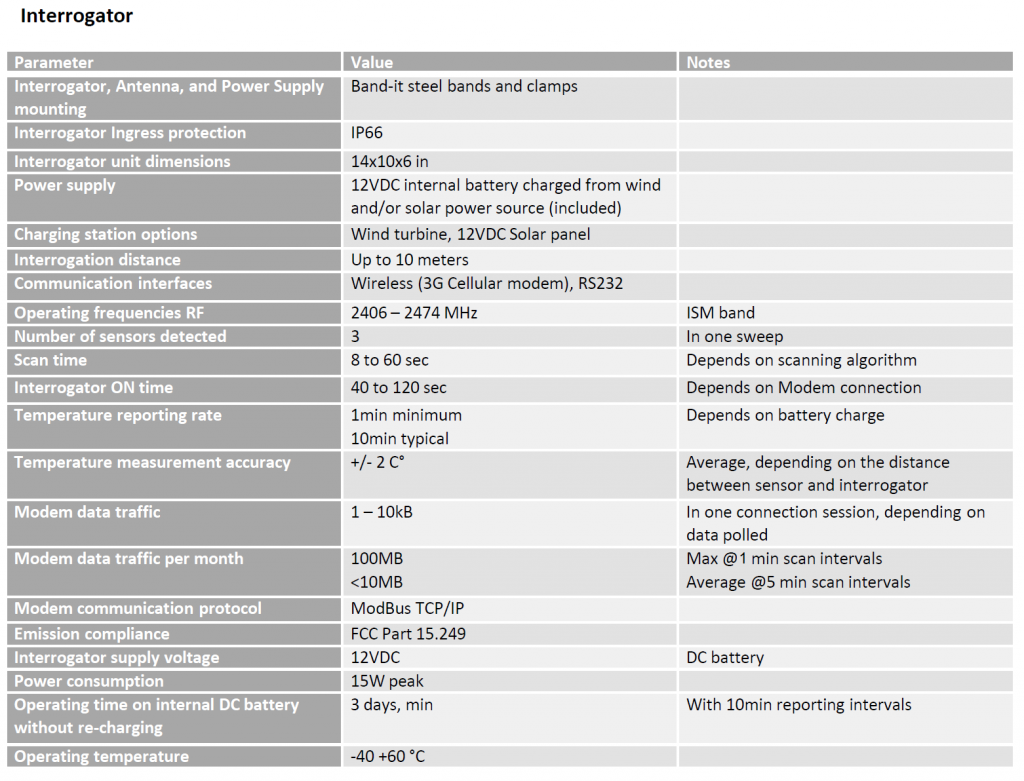

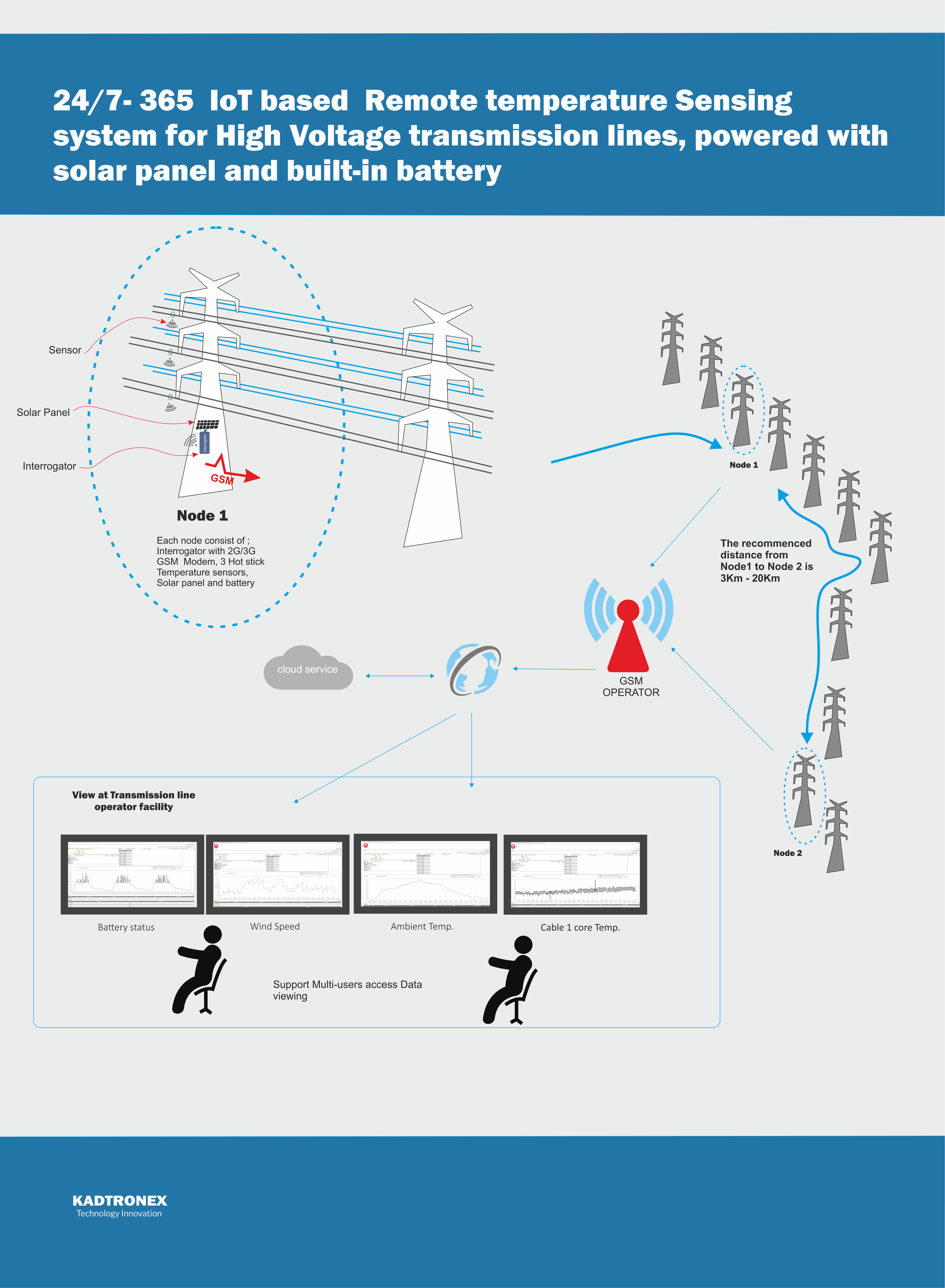

System Configuration

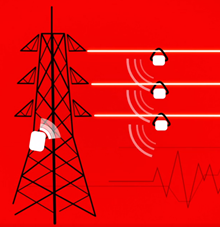

RT-RPLM Sensors are installed on one or more conductors; an Interrogator (“data receiver”) is installed on the transmission tower nearby. The Interrogator sends a microwave signal to the sensor and the sensor re-radiates at a frequency representing the sensor temperature. We can place several systems along the line (with spacing of one system every 10-20km) and compare the readings from these systems. Alternatively, place system at a critical spot where sag is most dangerous (i.e. near trains, highways, other lines, etc.)

Communications

The Interrogator receives the re-radiated signal, calculates a temperature value and transmits the information to a control center using a GSM/GPRS wireless data service.

Our Sensors are powered wirelessly by a Power base station inside the Interrogator Unit. This makes our technology unique on the market. Even in the Case of Power failure, the sensor will keep sending the status of the attached cable.